Our specialisation

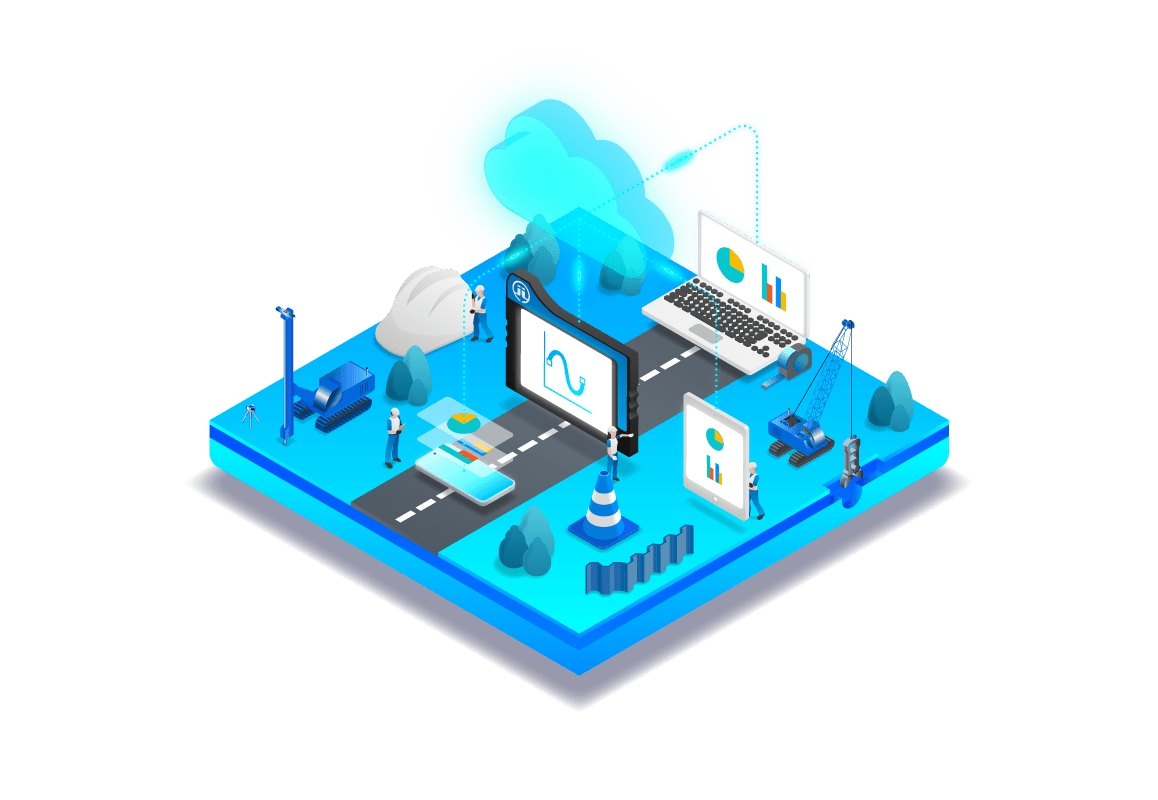

The Jean Lutz company specialises in the design, manufacture and implementation of sensors and special measurement and control devices for monitoring ground improvement techniques on major works worldwide, including deep foundation and geotechnical instrumentation used in the construction of dams, tunnels, subways and roads.

Quality control

Jean Lutz S.A.'s customer area allows the user to remotely monitor the progress of work carried out on a construction site on a remote display.

It offers the ability to check instrumentation settings and check the quality of work on the construction site by remotely viewing the operators screen.

Real time monitoring

Summary of activity phases

Management assistance

La collecte et l'accès instantané aux données depuis n'importe où offrent un potentiel d'optimisation unique.

Maintenance

Reduce the risk of plant breakdowns by effectively managing the maintenance of machines.

• Schedule and record maintenance.

Parameters

Check parameters in real time to ensure that the site is running correctly.

• Detailed digital data of all measurements recorded by the data logger.

Consumption

Monitor machine fuel consumption and cost effectiveness.

• Litres of fuel consumed per hour.

Instrumentation for deep foundations and soil investigation

High-precision data loggers and sensors for reliable, accurate measurements.